News

How Reshoring the Manufacturing of Your Thermal Management Solution Can Pay Off

Supply chain disruptions have been felt across all industries and have been particularly painful for those with products coming into American ports from abroad. A report from Flexport, a global logistics technology platform that uses a proprietary indicator to show...

Heat Pipe Design and Use

A well-designed heat pipe can efficiently transport large quantities of heat over a long distance. They are a valuable thermal management product used in applications across many industries, such as medical devices, power electronics, and aerospace and defense....

Our Shiny New Site is Now Live!

We are very excited to announce the launch of our newly designed website. After months of hard work and dedication, we are delighted to officially announce our live site! We wanted to make the new website faster, easier to navigate, and more user-friendly. Our goal...

A Message From Our President

Kevin, Gary, and Michael As 2021 starts, it is time to reflect back on 2020 and think about the path forward from a very unusual year. When I wrote a similar letter last year everything looked normal. There were no indications of a virus affecting our day to day...

How To Have A Long Successful Career: Absorb Everything You Can And Learn To Connect With People

For the past eight years, Carol Werner has been the face of purchasing at DAU, now known as KTK Thermal Technologies, and for the last 3 of those years, she has added human resources to her responsibilities. However, after a total of 46 years in manufacturing, on...

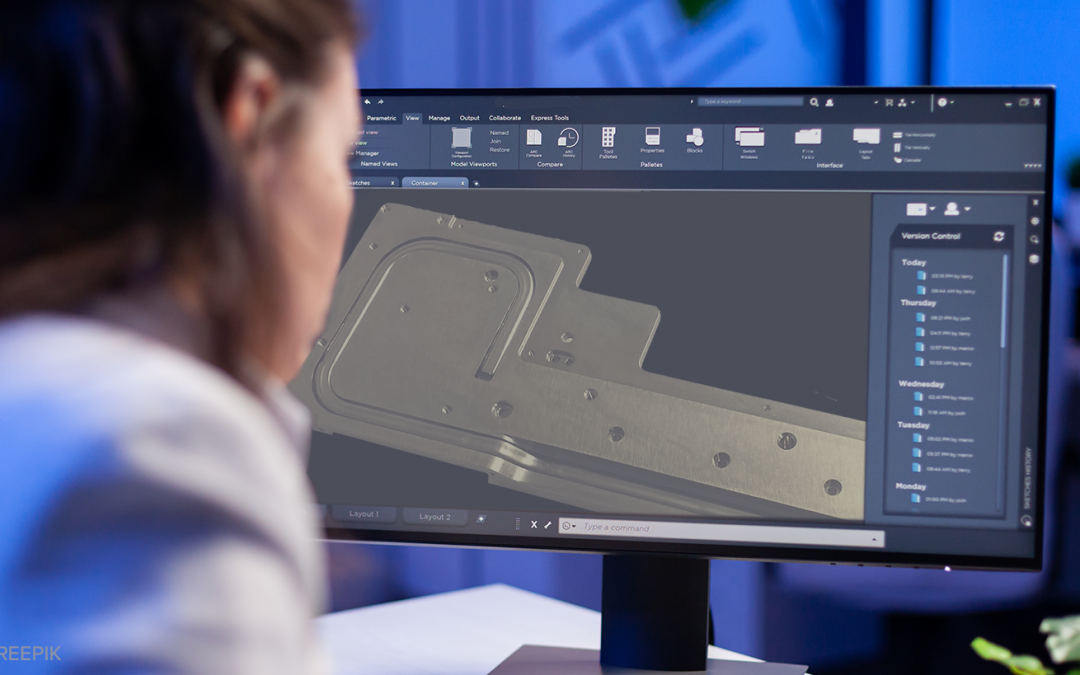

Saving Time and Money with 3D Printed Prototypes

Finding out that the form or fit of your thermal solution isn’t going to work after it’s manufactured can be costly. Sometimes mistakes happen, for example, a threaded hole on your ruggedized chassis is off on your CAD drawing by just enough to create a problem or...

A Letter From Our President

12 months. Sitting here writing this newsletter, 12 months seems like a long time. However, the last year has flown by since Michael, Gary, and I purchased Dau Thermal Solutions from the Miba Group in August 2018. The first few months were hectic, filled with the...

KTK Purchases New Equipment to Expand Capabilities and Increase Throughput

KTK has recently purchased two new pieces of equipment, demonstrating our commitment to continually invest back into the company to meet our customers’ growing needs for high-performance thermal management solutions. Haas VF6SS vertical machining center KTK has added...

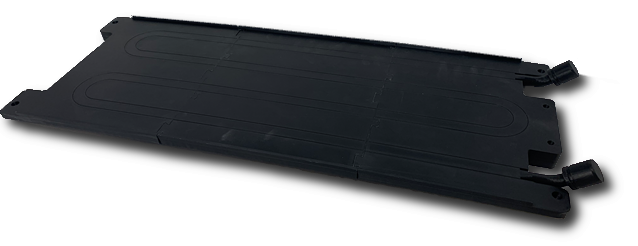

KTK to Supply Cold Plates for Columbia-Class Submarine

KTK Thermal Technologies is proud to announce they will be supplying two cold plates per boat on the Columbia-Class submarine through an awarded contract from Northrop Grumman Corp. The cold plates are the largest in size KTK has ever produced with one being over nine...

What does AS-9100 mean for our customers?

KTK Thermal Technologies recently received its AS-9100 recertification. The AS-900 standard provides suppliers with requirements for creating and maintaining a comprehensive quality system for providing safe and reliable products to the aviation, space, and defense...