Finding out that the form or fit of your thermal solution isn’t going to work after it’s manufactured can be costly. Sometimes mistakes happen, for example, a threaded hole on your ruggedized chassis is off on your CAD drawing by just enough to create a problem or maybe a connector tube isn’t matching up where you thought it would. In the past, this would mean starting over with new materials and machining – a waste of both time and money.

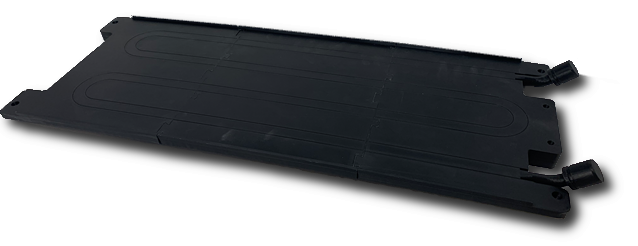

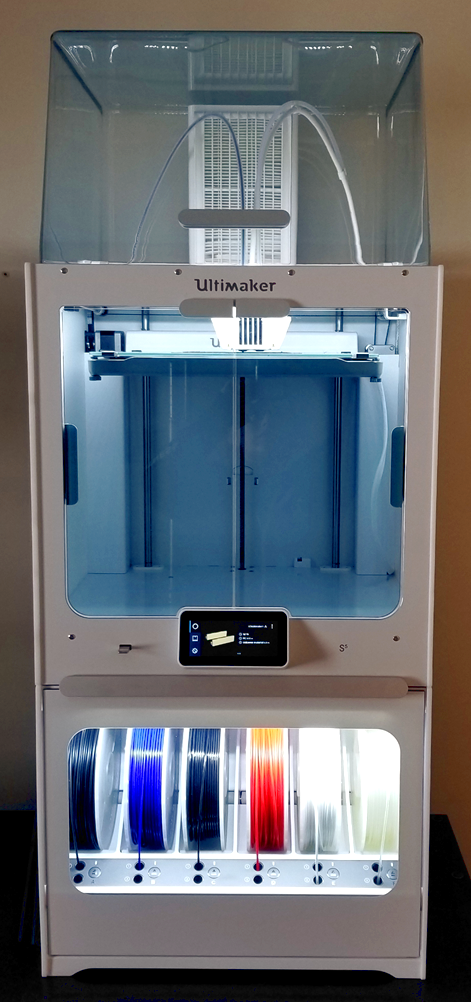

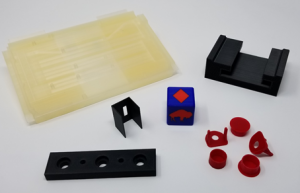

To remedy this, KTK Thermal Technologies has introduced additive technology to its prototyping processes. With the purchase of the Ultimaker 5S 3D printer with pro bundle, we are able to create 3D printed prototypes for our customers before ever machining a block of metal. This gives customers a sample they can physically touch and allows them to complete a form-fit test to ensure the part dimensions are correct and it will fit properly into the cabinet.

An additional benefit for our customers is speed. 3D printing is considerably faster than conventional prototyping methods, allowing you to get to production and, consequentially, to market faster.

Additionally, we are using the 3D printer to make tooling and fixturing that couldn’t be made with conventional manufacturing methods. These are helping to reduce set up time and, therefore, reduce costs.

The Ultimaker 5S delivers accurate, industrial-grade parts, and with dual extrusion and a 6-spool prefeeder, the printer can run longer and automatically switch between materials if needed. The Ultimaker 5S can run a variety of materials including stainless steel! It also boasts an impressive build volume of 330 x 240 x 300 mm (13 x 9.4 x 11.8 inches), which allows us to produce larger designs or print multiple parts on one plate.

The purchase of the Ultimaker 5S further demonstrates our commitment to continually invest back into the company to meet our customers’ growing needs for high-performance thermal management solutions.

With an eye on the future, we will continue to actively look at additive technology and how it can be incorporated further into our services.

With an eye on the future, we will continue to actively look at additive technology and how it can be incorporated further into our services.