Liquid Cooled

KTK Technologies’ evolving capabilities include custom-designed cold plates for applications that cannot be efficiently cooled with traditional heat exchanges.

What is a Cold Plate?

A cold plate, sometimes referred to as a water block, is a metal block (typically aluminum or copper) that possesses internal tubing to allow liquids to flow through it. The plate’s functionality is to provide localized cooling of power electronics. It does so by transferring heat from a device to a liquid (such as water or antifreeze) that flows to a remote heat exchange, and then dissipates into the ambient or to another liquid in a secondary cooling system. In layman’s terms, when a cold plate is placed on an electronic component that requires cooling, it absorbs and dissipates the heat from the component to the liquid that is then cycled through the system.

Compared to air cooling, liquid cold plates enable major reductions in the volume and weight of power electronics. Use of a cold plate is “the next step” when air-cooling falls short, often because thermal performance can no longer be economically met within the desired footprint.

Types of Cold Plates

Exposed Tube Cold Plates

Exposed tube cooled plates provide high-performance cooling in a smaller system.

Copper, copper-nickel, or stainless steel tubes are pressed into proprietary channels in an aluminum plate. A thermal epoxy is applied around the tube to provide optimal thermal transfer. The cold plates transfer heat from the device to the liquid in the tube, which is then moved through the closed loop system, dissipating the heat.

With an exposed tube liquid cold plate, the coolant tube is in direct contact with the device providing minimal thermal resistance and increased performance. Exposed tube cold plates are traditionally the cheapest of the liquid cooling technologies.

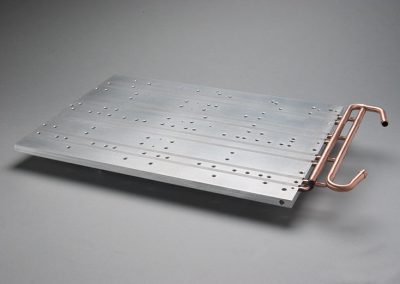

Buried Tube Cold Plate

A buried tube liquid cold plate has the ability to cool both sides of the cold plate. The tubes are protected from the outside environment. Generally, a copper tube is buried in an aluminum substrate machined by KTK. Next, a punched copper tube is pressed by a punching machine (this pressing is deeper than that of the exposed tube cold plate). Some engineers prefer the epoxy layer above the tube to protect the tube from leakage.

This cooling principle is best suited for high-power switching devices, such as chip, LED, and power battery cooling systems.

Deep Drilled Cold Plates

Deep drilled cold plates have multiple cooling channels drilled directly through the length of the plate. Tubing is inserted and expanded to create secure metal-to-metal contact, optimizing the thermal transfer properties and providing double-sided cooling. To further enhance cooling performance, a device called a “turbulator” can be added, which increases the flow velocity in the channels.

The benefits of deep drilled cold plate cooling are numerous:

- Allows for double-sided cooling

- Optimizes thermal transfer

- Turbulators can be added to enhance performance

- Smaller chance of leaks

You may be surprised to learn that few thermal engineering companies offer deep drilled cold plate applications, even though there is still a demand for it! KTK has the capabilities and acumen to accomplish deep plate drilling capabilities.

Vacuum Brazed and Dip Brazed Cold Plates

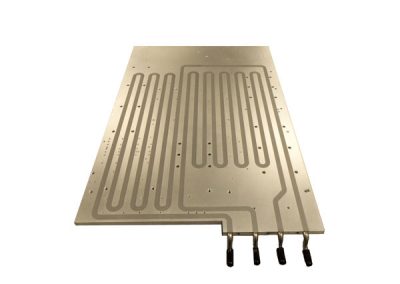

Vacuum Brazed Cold Plates

Vacuum brazing occurs when two cooling plates with internal channels and fin structures (often “folded” fins or “skived” fins) are sealed together inside a vacuum chamber for heating.

A filler metal with a lower melting point is melted into the joints of the cold plate via capillary action under the corresponding technological conditions, and connects two plates with internal channels and fin structures to form an internal flow channel. The vacuum system can be connected to the workpiece so that the pressure inside the workpiece is lower than the atmospheric pressure during vacuum brazing.

This cooling thermal module is frequently utilized in power generation, electric car batteries, fuel cell components, and other applications. Vacuum brazing has a higher cost , but also very high reliability.

Vacuum brazing poses many advantages:

- Highly repeatable and controllable batch processing

- Uniform material characteristics during and after brazing

- Significant flexibility with design, as it is not limited by the bending radius limitations of pressure tube cold plate

Dip Brazed Cold Plates

Dip brazed cold plates are as advantageous as vacuum-brazed cold plates, though the method of their creation differs. Here, instead of heating in a vacuum furnace, the two metal pieces are cleaned with chemicals, then go into a bath of molten salt (an aluminum brazing flux), heated up to near lava-level temperatures. The filler metal is pre-placed as close to the joints as possible.

Assembly is immersed or dipped, the molten flux comes in contact with all internal and external surfaces simultaneously. This liquid heat is extremely fast and uniform.

Tell Us About Your Application Needs

Not every cold plate system is appropriate for all devices that require cooling. Design and analysis cover a spectrum of performance features and considerations – from height and weight to temperature uniformity.

KTK Technologies has the capability to customizable specific cold plate design, depending on your application needs, including key factors such as:

- Tube path

- Manifolds

- Connectors

As always, our designs seek to minimize your operating and manufacturing costs. Contact us to discuss your needs today!