Supply chain disruptions have been felt across all industries and have been particularly painful for those with products coming into American ports from abroad. A report from Flexport, a global logistics technology platform that uses a proprietary indicator to show how long it takes to get products from factories to overseas destinations, shows the time for the transpacific eastbound trade lanes (running from Asia to North America) have been at or near high points in recent weeks. Although the times are slightly reduced from the November 2021 peak, they are still double the pre-pandemic Feb 2020 levels.

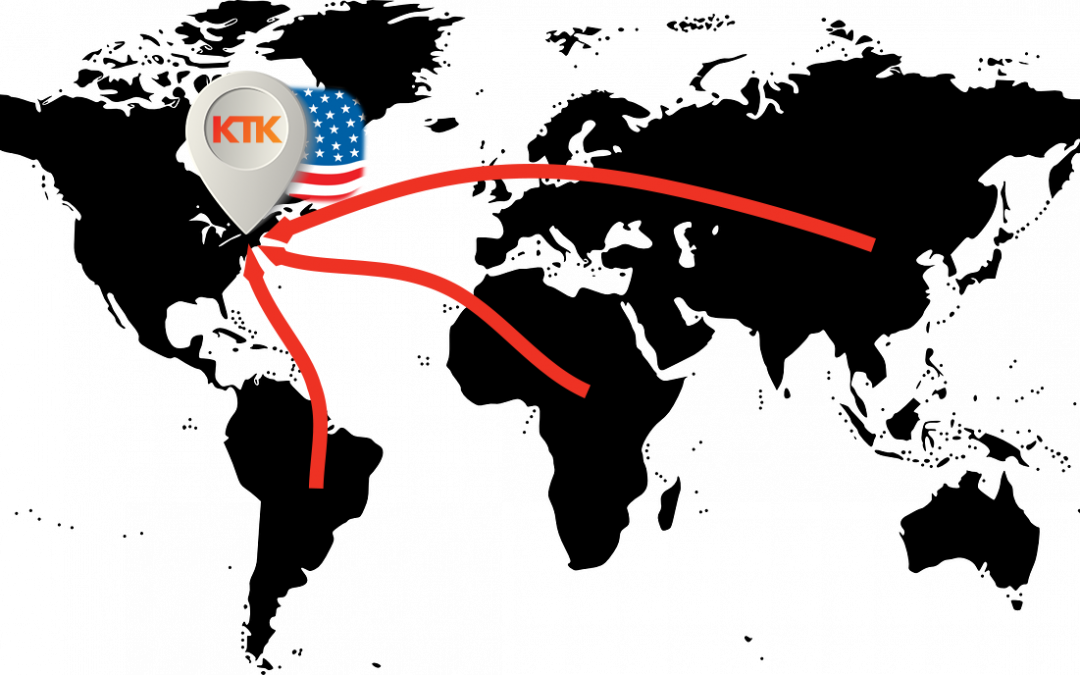

Two years of unpredictable lead times have created a logistical nightmare for many companies sourcing thermal management solutions abroad. This has led many to evaluate reshoring the manufacture of custom heat sinks, heat frames and chassis, and heat pipes. Although the supply chain crunch is felt domestically, it isn’t creating the same level of delays. A domestic supplier can more efficiently meet your needs if they change unexpectedly or offer suggestions for an alternative that can be delivered more quickly. Offshore manufacturers do not have the luxury of flexibility with speed.

In addition to reducing lead times, reshoring custom thermal management solutions bring additional benefits, including economic and environmental impacts.

Reshoring May Reduce Costs

Even before the pandemic, some companies were becoming more aware that the total landed costs associated with offshoring were rising. Still, for others, the pandemic has taught a hard lesson about the ineffectiveness of offshore supply chains. Many of the cost-saving advantages of offshoring no longer provide a competitive advantage. Rising labor costs, higher freight charges, and tariff costs are taking a bite out of profits. Fluctuating currency, government instability, difficult communication between two different languages, and risks to intellectual property have the potential to obliterate profits. Buying from countries like China requires upfront funding of the inventory, whereas domestic manufacturers may provide you with payment terms that can increase your cash flow. There are also costs associated with maintaining and managing inventory. And finally, if your custom thermal management solution arrives damaged or has quality issues, it is more difficult to resolve the problem. If the manufacturer does replace it, you are still at the mercy of the overseas supply chain.

Environmental Issues Related to Offshoring

Many companies are taking a closer look at their carbon footprint, whether because of customer pressure or a need to fulfill sustainability objectives. Manufacturing offshore can significantly add to a company’s carbon footprint. Many countries where products are offshored have relaxed or non-existent environmental regulations. Developing countries tend to have higher carbon emissions from using coal for energy generation and have higher pollution levels. This is in addition to the environmental impact of long-distance travel across oceans. CDP, a non-profit climate research provider, reports that the greenhouse gas emissions in supply chains are, on average, four times more than those of the company’s direct operations. Sourcing domestically can reduce your carbon foot print.

Thermal Management Solutions Manufactured in the USA

Not all domestic thermal management solution providers are created equal. If you are looking for a domestically made custom solution to solve your tough thermal management challenges, look no further than KTK Thermal. Our design engineers have extensive experience in thermal management design, prototyping, and manufacturing. We offer thermal interface design and simulation, CFD simulation, thermal and infrared thermal testing, and a high level of customer service you won’t get from offshore providers. Contact us to learn how we can help you with your next project.