Engineering & Testing Capabilities

At KTK, our goal is to assist our clients in developing their ideal designs, providing them with the necessary tools and resources to bring their ideas to life. We act as an extension to our customer’s engineering team, enhancing perspectives and offering development and testing protocols that aid in the completion and production of a design.

Our core offerings include:

- Thermal management design

- Prototyping

- Manufacturing/Production

When partnering with clients, our general process involves the following steps in order to gain a full understanding and development of our client’s ideas and how to create them in a manufacturable manner.

Our Process:

- Fill out datasheet

- Design Assistance

- Simulation

- Prototyping

- Product manufacturing

- Testing Capabilities

Thermal Management Design

At KTK, we have the capability to assist with engineering customized, high-performance thermal solutions that enable your product to achieve its full potential. Our thermal engineers have extensive experience participating in thermal management design, prototyping, and manufacturing. We understand your project challenges at an engineering level.

Our thermal management design capabilities include:

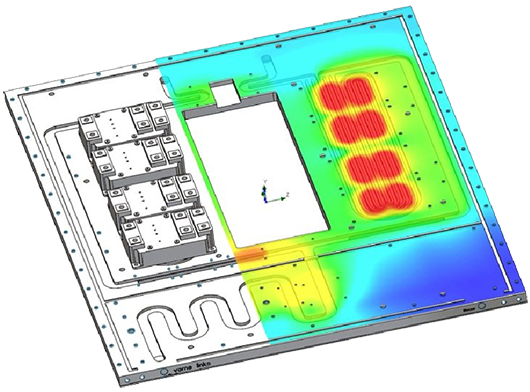

CFD thermal simulation

This thermal simulation offers the highest and most accurate results possible. We create a thermal study to solve complex equations and provide you with our best resources.

3D CAD / CAM

This is our 3D simulation software, SolidWorks, which provides a general and efficient look at design concepts.

Quick thermal calculators

These provide a quick and accurate understanding of the numbers for our clients who are looking for fast efficiency. We offer:

- Natural

- Forced Air

Prototyping

We provide short-run prototypes in order to prove design functionality, providing our customers with the assurance that their product works before investing further into the process. This short-run prototype allows us to evaluate the form and function of a product before moving on to manufacturing. This saves our clients time and money and creates a collaborative atmosphere that encourages client communication. Once our client evaluates their prototype and expresses satisfaction with all elements of the design, we then move on to production.

Production

KTK is proud to offer in-house only manufacturing. At this stage, fixtures become more robust and we engage in high-volume production runs. We ensure every product that ends up in production has complete client approval. We are deeply invested in our design and prototyping process so that production is free of any issues. Customer satisfaction is always our priority.

Capabilities

At KTK, we are committed to offering a unique and fulfilling experience, providing each customer with options and creative solutions. Some of our additional capabilities include:

Pressure Testing

Upon client request, we offer additional testing during the prototyping stage.

CNC Deep Hole Drilling

To provide a wider variety of options for our clients, we offer two horizontal CNC machines capable of deeper hole drilling. These provide the ability to spindle through coolant as well as drill water paths inside of a cold plate.

Why work with KTK

At KTK, our intention is always to provide the most efficient and seamless development environment possible. We are committed to client communication and always work to maintain a strong collaborative environment built on honesty and creative problem-solving. We pride ourselves on being easy to work with and strive to maintain open dialogue as the key to a hassle-free collaboration. KTK provides diverse manufacturing techniques at affordable prices, striving to meet top thermal performance standards at every opportunity.