Heat Frames & Chassis

At KTK, our heat frames and chassis are mainly produced for aerospace and defense applications. Our ruggedized chassis are essential to aid in protection against the shock and vibrations involved in the defense and aerospace industries.

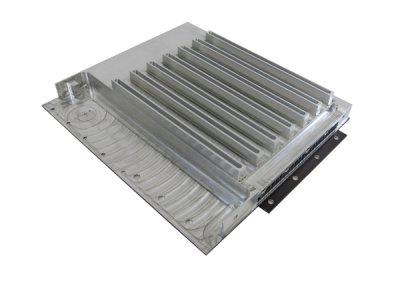

RUGGEDIZED HEAT FRAMES

Ruggedized heat frames are precision machined out of aluminum or copper material and provide a low resistance path for heat flow from the circuit board to the heat sink. The heat frame offers structural reinforcement for high shock and vibration applications.

RUGGEDIZED CHASSIS

KTK’s conduction-cooled chassis are designed for rugged applications that require optimal thermal dissipation. The chassis are high-precision machined boxes that provide a cold wall to cool and support heat frames without the need for a heat sink. Conduction-cooled, liquid-cooled, and air-cooled options are available.

How It Works

The structure of our chassis and heat frames allows for an ideal heat exchange process. The card slots within a chassis hold the heat frames that PCB boards attach to. The heat frame provides the following functions:

- Provides rigid support and structure to the PCB board against shocks, such as the vibrations in an airplane

- Interacts with the chassis and utilizes conduction cooling to cool down the PCB board

Heat frames are made from aluminum and copper and are typically anodized to provide a protective cover.

There are several different types of heat frames, but the most common are:

- Welded

- Dip Brazed

- Gasketed

- Vacuum Brazed

- Embedded Heat Pipes

While all of the above are great options, we most commonly utilize dip brazing at KTK for heat frame and chassis uses. This process is carried out using molten salt (salt that has been heated to a temperature rendering it liquid). The parts are dipped in the molten salt and joined together. When cooled, this process provides some of the strongest results with the least likelihood of joint fracture because the material essentially become one.

Moving Forward

As this industry continues to grow and evolve, we are anticipating the exciting introduction of two new heat frame specs. KTK will soon be offering the VITA 48.8 Air Cooled Heat Frame, as well as the VITA 48.4 Liquid Cooled Heat Frame. Currently the industry’s top heat frames, we are excited for the positive impact and versatility this will provide our clients. In the near future, we will also be implementing additive manufacturing methods, offering 3D printing of metals.

As a company, we continue to invest in our growth and seek out better and more effective ways to assist our clients in all of their varying projects.

Talk to a KTK Thermal Engineer today to find unique and personalized solutions for your projects.