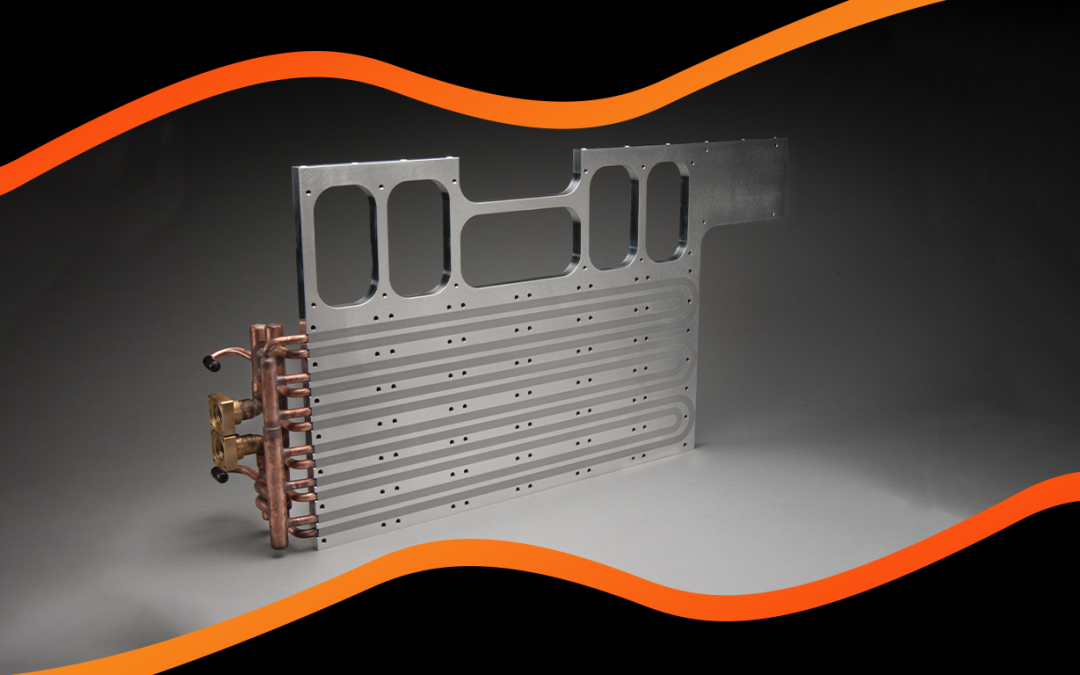

Liquid cold plates, sometimes called water blocks, are used for the thermal management of compact, high-power electronic applications where conventional air-cooled heat sinks are not feasible because of size or weight limitations.

The plate is typically aluminum or copper with internal tubing that allows fluid to run through. The heat generated from the electronic device is transferred through the conductive plate to the fluid. The fluid is pumped through a heat exchanger and back through the tubes to the cold plate, creating a cooling loop.

Common Fluids for Liquid Cooling

Choosing the right working liquid for the liquid cold plate is critical for proper heat transfer and operational efficiency. The type of fluid will depend on the application, but generally speaking, it should have high thermal conductivity and be compatible with the system’s materials.

The fluids used in the liquid cold plate are typically water or water and glycol. However, other liquids can be used for unique applications.

Water offers superior heat transfer properties, but corrosion should be considered for some materials. Additionally, chlorine and other impurities found in many tap waters may also create issues with corrosion or clog fluid channels. Water should be high quality or deionized. Another problem with using pure water is freezing. If the application will be exposed to below-freezing temperatures, water on its own is not a feasible choice. Often glycol will be added to prevent freezing.

As glycol is added, the freezing temperature lowers, but the heat transfer properties are reduced. So, using the lowest amount possible for the application’s temperature requirements is necessary.

The two types of glycol typically used are ethylene glycol and propylene glycol.

Ethylene glycol has many desirable properties for thermal management in liquid cold plates, including a high boiling point, low freezing point, high specific heat (heat required to raise the temperature one degree Celsius), and thermal conductivity.

Propylene glycol, which is often used in food applications, is not toxic like ethylene glycol is. Although the properties of propylene glycol are not as desirable as ethylene glycol, it can be used in applications where toxicity might be a concern.

KTK for Your Customized High-Performance Thermal Solutions

As engineers, we understand your project challenges, and we will work with you to find the correct solution. We typically use water and glycol for liquid cold plates but have engineered systems with unique requirements that require an unusual cooling liquid, such as jet fuel. We have also engineered cold plates that will work with fluids readily available in the field. In one case, it was swamp water. Our engineers are masters of divergent thinking and will find a solution that fits your unique needs.

Whether you require liquid cooling or another thermal solution, we can engineer a customized, high-performance thermal solution that will enable your product to achieve its full potential.

Contact us to learn more.