Efficient thermal management in power electronic applications is crucial, particularly as power density in these products continue to increase. Failure to keep critical components at their optimal operating temperature will negatively impact reliability and service life, ultimately resulting in catastrophic failure.

Traditionally, air-cooled heat sinks have been the method used for cooling power electronics. However, as engineers continue to develop more compact applications with higher power densities, conventional air-cooled heat sinks are no longer sufficient. Liquid cooling is a more efficient way to remove excess heat from the critical components.

Compared to air, the liquids used in liquid cooled heat sinks have a higher heat density, heat capacity, and thermal conductivity, lending themselves to being the ideal medium for dependable thermal management. The liquid-cooled heat sink consists of liquid within tubes that flow through a thermally conductive cold plate. When the component generates heat, it travels through the cold plate to the liquid, which it is pumped through a heat exchanger and back through the tubes to the cold plate, creating a cooling loop.

KTK Custom Liquid Cooled Heat Sinks

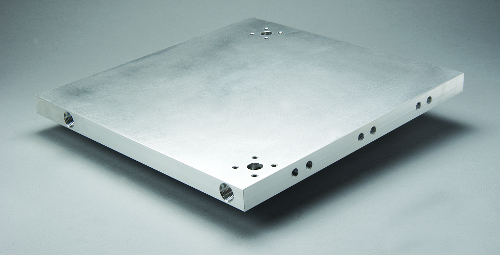

KTK Thermal offers exposed tube, buried tube and deep drilled cold plates. Our exposed and buried tube cold plates feature copper, copper-nickel, or stainless steel tubes that are pressed into proprietary channels in an aluminum plate. We then apply a special thermal epoxy around the tube to provide optimal thermal transfer.

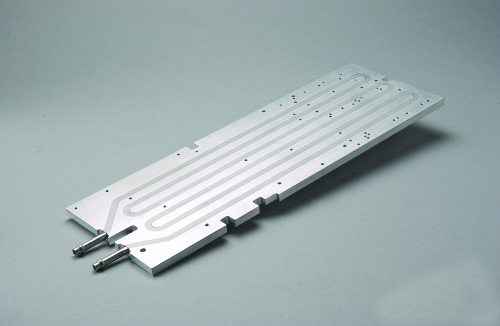

With the exposed tube liquid cold plate, the coolant tube is in direct contact with the device, providing minimal thermal resistance and increased performance. The buried tube liquid cold plate can cool both sides of the cold plate, and the tubes are protected from the outside environment. The tube path, manifolds, and connectors can be customized depending on the need.

KTK’s deep drilled cold plates have multiple cooling channels drilled directly through the length of the plate. Tubes can be installed to create secure metal-to-metal contact, optimizing the thermal transfer properties and providing double-sided cooling. When further cooling is required, turbulators can be added. Turbulators increase cooling velocity by creating turbulent flow through the channels.

Need Help Deciding?

If you are not sure what type of heat dissipating product you need, KTK thermal can help. KTK takes on projects other company’s shy away from. Its design engineers have extensive experience in thermal management design, prototyping, and manufacturing and can help you find the right solution for even the most challenging applications.